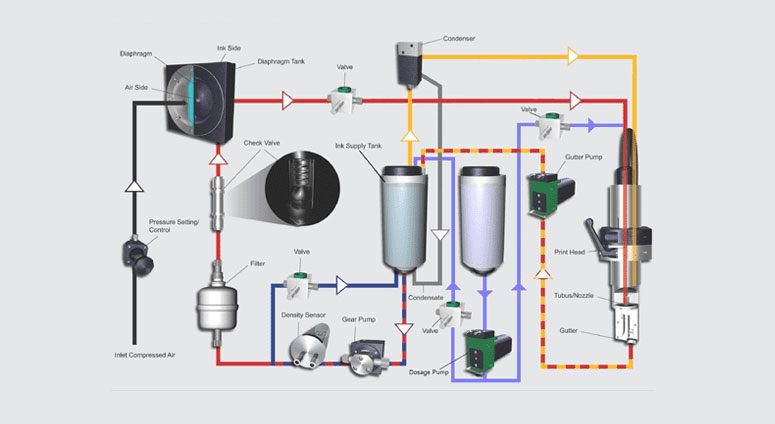

From the ink tank, the ink is fed through a pressure pump past the pressure sensor into the tubus in the print head. The ink in the tubus is forced to be modulated with the aid of the piezo oscillator controlled by the modulation module. The ink in the tubus breaks down into a stream of separate drops from a solid state, as it emerges through a fine nozzle. The ink drops break off when passing through the range of a charge electrode. All ink drops pass through the electrostatic field set up between the two high voltage deflector plates.

The charged drops are deflected in the direction of the electrostatic field and fly past the gutter tube onto the printing surface. The uncharged drops, which are not deflected, fly straight on and are sucked up by the gutter tube. The return suction pump recycles the ink from the gutter tube into the ink tank. This way the inkjet operates according to the continuous inkjet principle

From the ink tank, the ink is fed through a pressure pump past the pressure sensor into the tubus in the print head. The ink in the tubus is forced to be modulated with the aid of the piezo oscillator controlled by the modulation module. The ink in the tubus breaks down into a stream of separate drops from a solid state, as it emerges through a fine nozzle. The ink drops break off when passing through the range of a charge electrode. All ink drops pass through the electrostatic field set up between the two high voltage deflector plates.